- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

Material selection and performance requirements of military forgings: the combination of precision and excellence

- Category: Steel forgings, Thermal forging

- |

- Date: 15/12/2023

Through scientific and reasonable material selection and process design, it can meet the high standard requirements of military forgings and provide strong support for the development of military equipment. At the same time, with the continuous progress and innovative development of science and technology, the material selection and performance requirements of military forgings in the future will continue to expand and improve.

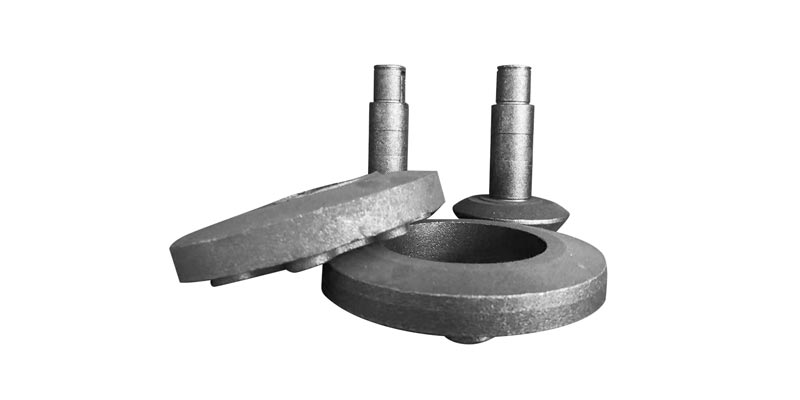

Product Details

Military forgings are an important part of military equipment manufacturing, and their material selection and performance requirements are directly related to the performance and reliability of the equipment. This paper will introduce the material selection and performance requirements of military forgings in detail.

First, material selection: the combination of high performance and special needs

High-strength alloy steel: In military forgings, high-strength alloy steel is one of the most commonly used materials. This material has excellent strength, toughness and corrosion resistance, and can withstand high strength loads in complex environments. Therefore, high-strength alloy steel has a wide range of applications in the manufacture of key components and structural parts.

Titanium alloy: Titanium alloy is a lightweight, high-strength metal material with excellent corrosion resistance and high temperature properties. In the military industry, titanium alloy is widely used in the manufacture of aerospace, Marine engineering and other fields of structural parts. Due to its light weight and high strength characteristics, titanium alloys can reduce the overall weight of equipment and improve mobility and combat performance.

Other special materials: In addition to high-strength alloy steel and titanium alloy, there are some special materials used in military forgings. For example, some composites have excellent strength and toughness to meet the needs of specific application scenarios. In addition, some new high-performance materials are also being developed and applied.

Second, performance requirements: precision and stability of the unity

Precision: Military forgings need to have a high degree of precision to ensure the accuracy and stability of equipment. Therefore, in the material selection and manufacturing process, a series of measures need to be taken to ensure the dimensional accuracy and shape accuracy of the parts. For example, the use of advanced processing equipment and technology, accurate heat treatment and surface treatment.

Stability: Stability is one of the important performance requirements of military forgings. In military applications, equipment needs to operate stably for a long time and withstand the effects of various complex environments. Therefore, military forgings need to have excellent stability and durability to ensure the safety and reliability of equipment.

Fatigue resistance: Fatigue is one of the important reasons for the damage of mechanical parts. In the process of design and manufacture of military forgings, it is necessary to fully consider the anti-fatigue properties of materials and take effective process measures to improve the fatigue life of components. This includes optimizing the material composition, selecting the appropriate heat treatment process, and conducting fatigue tests.

Corrosion resistance: In military applications, forgings often need to face complex environmental conditions, such as oceans, deserts, etc. Therefore, material selection and surface treatment need to have good corrosion resistance to extend the service life of the parts. This can be achieved through the selection of materials with corrosion resistance, surface treatment and coating protection.

Machinability: In order to meet the design requirements of complex components, the material should have good machinability. This includes thermal processing, cold processing, welding and other process properties to ensure the smooth progress of the manufacturing process. At the same time, factors such as the machinable cost and efficiency of the material need to be considered.

In summary, the material selection and performance requirements of military forgings have strict characteristics. In the selection of materials, it is necessary to consider the requirements of high performance and special needs; In terms of performance requirements, factors such as precision, stability, fatigue resistance, corrosion resistance and machinability should be fully considered. Through scientific and reasonable material selection and process design, it can meet the high standard requirements of military forgings and provide strong support for the development of military equipment. At the same time, with the continuous progress and innovative development of science and technology, the material selection and performance requirements of military forgings in the future will continue to expand and improve.

nannan

INNALLY website editing, to provide you with forging related information

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.