- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

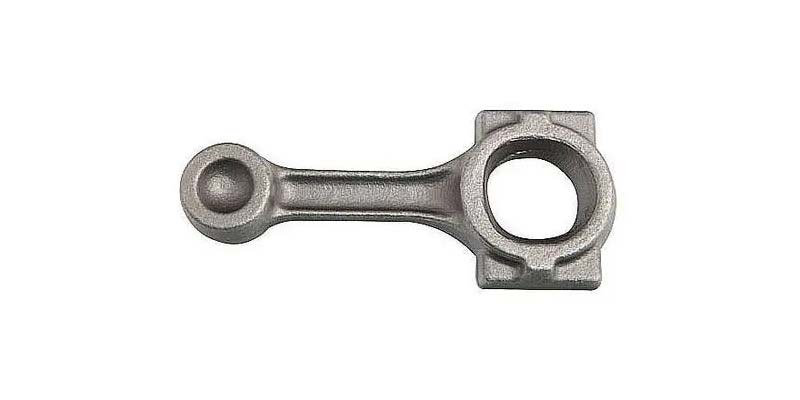

How to improve the quality of connecting rod forging?

- Category: Steel forgings, Thermal forging

- |

- Date: 16/11/2023

improving the quality of connecting rod forgings needs to be controlled and managed from many aspects such as raw material selection, process formulation, heat treatment, inspection and measurement. Through continuous improvement and innovation, the quality and performance of connecting rod forgings can be improved, the production cost can be reduced, and the competitiveness of enterprises can be improved.

Product Details

Improving the quality of connecting rod forging is the key to ensure engine performance and life. Here are some ways to improve the quality of connecting rod forgings:

Selection of high-quality materials: The selection of high-quality steel or aluminum alloy materials can ensure the strength and stiffness of the connecting rod forging, while improving its corrosion resistance and service life.

Accurate forging process: The use of accurate forging processes, such as hot die forging, cold precision forging, etc., can reduce material waste and reduce residual stress, while improving the accuracy and consistency of connecting rod forgings.

Appropriate heat treatment: Appropriate heat treatment can improve the microstructure and mechanical properties of connecting rod forging materials, improve its strength, toughness and corrosion resistance.

Strict inspection and measurement: Strict inspection and measurement of connecting rod forgings can ensure that their dimensional accuracy, shape accuracy and surface quality meet the requirements and prevent the appearance of unqualified products. mining

With advanced process technology: The use of advanced process technology, such as numerical simulation technology, laser shock strengthening technology, can optimize the design and manufacturing process of connecting rod forgings, improve its quality and performance.

Strengthen quality control: Establish a sound quality control system, and comprehensively monitor the raw materials, processing processes, and finished products of connecting rod forgings to ensure that the quality of each link meets the requirements.

Experience accumulation and continuous improvement: continuous accumulation of experience in the production process and continuous improvement in response to problems can improve production efficiency and product quality and reduce production costs.

In short, improving the quality of connecting rod forgings needs to be controlled and managed from many aspects such as raw material selection, process formulation, heat treatment, inspection and measurement. Through continuous improvement and innovation, the quality and performance of connecting rod forgings can be improved, the production cost can be reduced, and the competitiveness of enterprises can be improved.

nannan

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.