- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

Basic manufacturing process of bearing forgings

- Category: Metal forging, Steel forgings

- |

- Date: 03/11/2023

the manufacturing process of bearing forgings is a complex and rigorous process, involving multiple links and strict quality control. Each step requires superb craftsmanship and professional equipment support to ensure the highest level of quality and performance of the final product.

Product Details

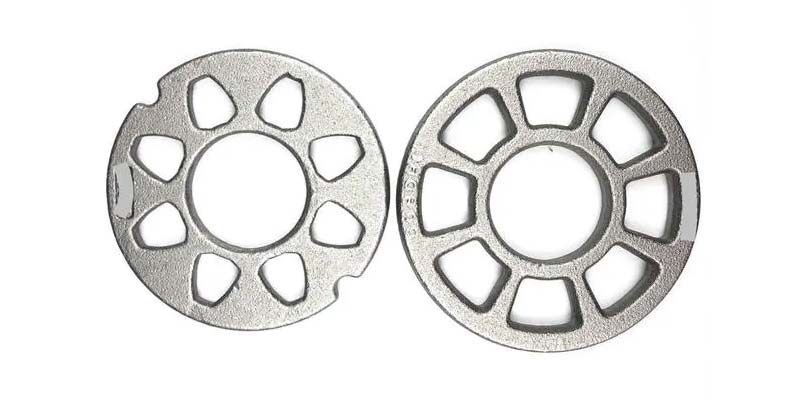

Bearing forging is an important mechanical part, which is widely used in various mechanical equipment. The manufacturing process mainly includes the following steps:

First, raw material preparation

The first step in the manufacture of bearing forgings is to prepare raw materials. Usually, bearing forgings require the use of high-quality steel, such as alloy steel, stainless steel, etc. These steels require strict quality control to ensure that their chemical composition, metallographic structure and mechanical properties meet the requirements.

Two, heating

Heating steel to the proper temperature is one of the key steps in the manufacture of bearing forgings. The purpose of heating is to make the steel have enough plasticity and deformation ability to facilitate the forging process. At the same time, heating can also eliminate the stress inside the steel and improve its mechanical properties.

Three, forging

Forging is the core step of bearing forging manufacturing. In this process, the heated steel is fed into the forging equipment for deformation treatment. Usually, forging equipment includes forging hammer, press and forging machine. In the forging process, the steel needs to be repeatedly deformed, corrected and processed according to the drawings and technical requirements until the desired shape and size are reached.

- Heat Treatment

Heat treatment is an indispensable step in the manufacture of bearing forgings. After forging is completed, the steel needs to be heat treated to remove internal stresses and improve its hardness and wear resistance. The process of heat treatment usually includes quenching, tempering and surface treatment.

- Processing and inspection

Bearing forgings after heat treatment need to be further processed and inspected. This process includes machining operations such as turning, drilling and milling, as well as inspection of dimensional accuracy, shape accuracy and surface quality. Only bearing forgings that meet the requirements can be regarded as qualified products.

- Anti-rust treatment

In order to prevent bearing forgings from being corroded during storage and use, anti-rust treatment is required. The process includes steps such as cleaning, painting and packaging. The bearing forgings after anti-rust treatment can maintain their original performance and quality for a long time.

In short, the manufacturing process of bearing forgings is a complex and rigorous process, involving multiple links and strict quality control. Each step requires superb craftsmanship and professional equipment support to ensure the highest level of quality and performance of the final product.

nannan

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.