- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

What do you want to know about the quality and performance of metal forgings?

- Category: Metal forging, Steel forgings

- |

- Date: 18/09/2023

In summary, metal forgings have an important position and role in the industrial field. They not only have high precision and excellent mechanical properties, but also significantly improve the stability and reliability of the equipment. By communicating and building relationships with target customers, we will provide you with the best quality products and services. If you need, please feel free to contact us!

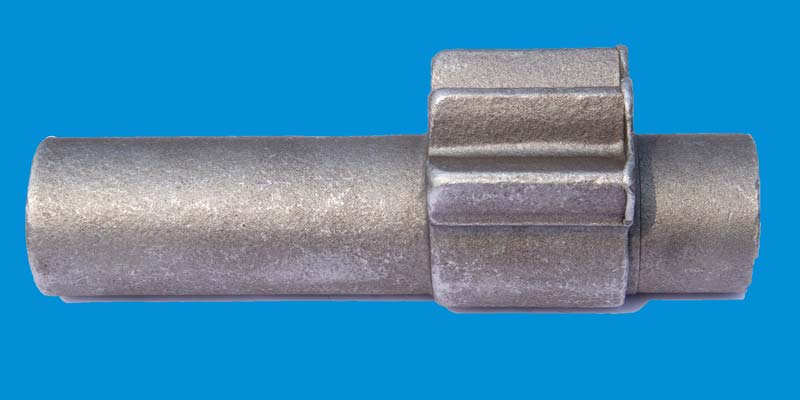

Product Details

In today’s industrial field, the application of metal forgings is more and more extensive, they are not only an important part of mechanical equipment, but also play a vital role in improving the performance and quality of equipment. So, about the quality and performance of hardware forgings, what aspects should we pay attention to?

First of all, let’s take a look at the basic information of hardware forgings. Metal forging is a kind of metal parts made by forging process, with high strength, hardness and wear resistance. They are widely used in various industries, such as automotive, aerospace, energy, etc. With the continuous progress of science and technology, the market demand is also increasing.

Next, let’s delve into the quality and performance of hardware forgings. High quality metal forgings have the following characteristics:

Excellent material: High quality metal forgings using high-quality raw materials, through strict smelting and forging process to ensure its inherent quality.

High precision: Through advanced forging equipment and process, high precision metal forgings can be obtained, thus ensuring the stability and reliability of the equipment.

Excellent mechanical properties: After high temperature forging and cooling treatment, metal forgings can obtain excellent mechanical properties, such as high strength, high hardness, good wear resistance and fatigue resistance.

Strong corrosion resistance: Some metal forgings will be surface treated during the manufacturing process, such as galvanizing, painting, etc., to improve their corrosion resistance.

So, in practical applications, what role can metal forgings play? Let’s look at a practical case. In the automobile manufacturing industry, the engine is one of the core components of the car. The cylinder liner and piston rings in the engine are made of metal forgings. High-quality cylinder liner and piston ring not only have high precision and excellent mechanical properties, but also improve the efficiency and power of the engine, reducing fuel consumption and emissions.

So, for companies that have the intention to buy hardware forgings, how should they communicate and establish relationships with target customers? Releasing product information and related industry information on social media platforms is an effective way. It is also a good choice to attend the exhibition, which can not only show the strength of the company and product characteristics, but also communicate with potential customers face to face. In addition, regular customer visits are also an important means of building long-term relationships.

In summary, metal forgings have an important position and role in the industrial field. They not only have high precision and excellent mechanical properties, but also significantly improve the stability and reliability of the equipment. By communicating and building relationships with target customers, we will provide you with the best quality products and services. If you need, please feel free to contact us!

nannan

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.