- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

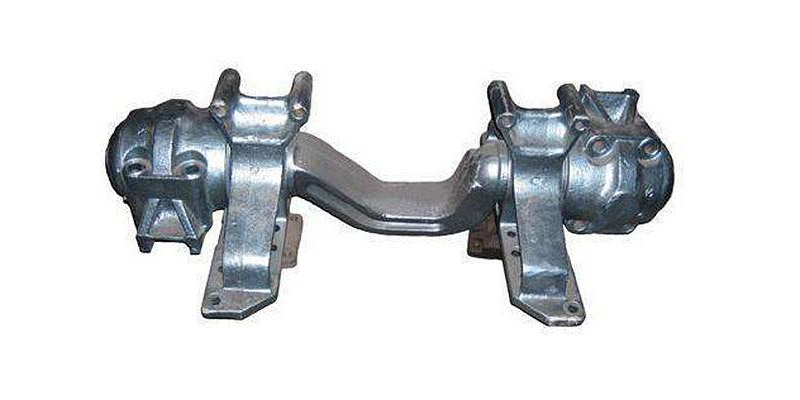

What is a car balance shaft?

- Category: Automotive forgings, Steel forgings

- |

- Date: 23/08/2023

Automotive balance shaft is an important device used to reduce engine vibration and vibration. It adopts the principle of relative rotating mass or inertia, and by introducing a balance block or adjusting the geometry of the shaft, the unbalanced force and torque tend to balance when the engine is working, and improve the running smoothness and comfort of the engine.

- Can be customized according to the specific model

Product Details

Automotive balance shaft is an important device used to reduce engine vibration and vibration. It adopts the principle of relative rotating mass or inertia, and by introducing a balance block or adjusting the geometry of the shaft, the unbalanced force and torque tend to balance when the engine is working, and improve the running smoothness and comfort of the engine. Below we will introduce the definition, working principle and application in automotive engineering in detail.

First of all, the automobile balance shaft is a specially designed shaft, its main role is to reduce the unbalanced force and torque generated in the rotating motion. In general, the balance shaft will add some additional mass called a balance block to the rotor, or by adjusting the geometry of the shaft to achieve the adjustment of the mass distribution. In this way, the balance shaft presents a rotating state relative to the rotating axis when the engine is working.

Secondly, the working principle of the automobile balance shaft is based on the dynamic principle and vibration control theory. During engine operation, due to the uneven mass distribution of rotating parts, a physical phenomenon called unbalanced force and torque will be generated. This force and torque will cause the engine to produce vibration and vibration, and will be transmitted to the car body and the driver and passenger, affecting the smoothness and comfort of the car. The introduction of the balance shaft can offset the unbalanced force and torque by generating opposite forces and torque, thus making the engine run more smoothly.

In automotive engineering, automotive balance shafts are widely used in various types of internal combustion engines to improve engine ride and comfort. By reducing the generation of unbalanced forces and torque inside the engine, the balance shaft can effectively reduce mechanical noise and vibration, and improve driving comfort. At the same time, it can also reduce the torque shock of the transmission system and extend the service life of the engine and transmission system. In addition, the use of balance shaft technology can also improve engine combustion efficiency, reduce fuel consumption and emissions.

It should be noted that the design and manufacture of automotive balance shafts need to consider the selection of materials and the optimization of geometric shapes. Reasonable selection of materials can ensure the strength and reliability of the balance shaft, while meeting the requirements of high temperature and high pressure in the engine working environment. The optimization of the geometric shape can make the mass distribution of the balance shaft more reasonable to achieve the best vibration control effect.

In summary, the automotive balance shaft is a device used to reduce engine vibration and vibration, by introducing a balance block or adjusting the geometry of the shaft, to achieve the balance of the unbalanced force and torque in the process of engine rotation. Its application in automotive engineering can effectively improve the running stability and comfort of the engine, reduce noise and vibration, extend the service life of mechanical parts, improve combustion efficiency, reduce fuel consumption and emissions. With the progress of technology and the accumulation of application experience, the design and manufacture of automotive balance shaft will be more widely promoted and applied.

ayu

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.