- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

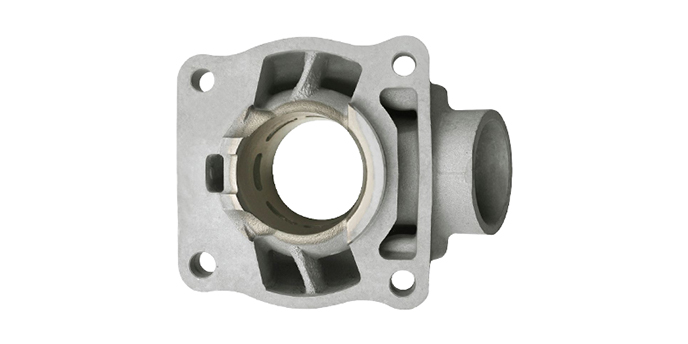

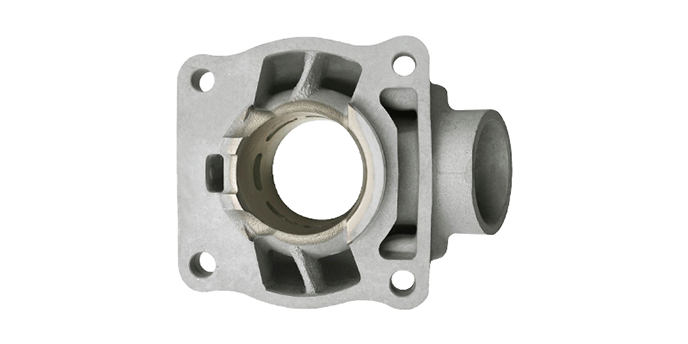

What is locomotive cylinder body forging?

- Category: Locomotive forging, Steel forgings

- |

- Date: 16/08/2023

ocomotive cylinder body forgings are made of high-strength steel through a specific forging process, which has high precision and corrosion resistance. It not only meets the requirements of stable operation and efficient output of locomotive engines, but also maintains long-term reliability in complex and harsh working environments.

- Can be customized according to the specific model

Product Details

Locomotive cylinder body forging is an important part of locomotive engine, which carries the function of combustion chamber and cylinder. Locomotive cylinder body forgings are made of high-strength steel through a specific forging process, which has high precision and corrosion resistance. It not only meets the requirements of stable operation and efficient output of locomotive engines, but also maintains long-term reliability in complex and harsh working environments.

In a locomotive engine, the combustion chamber carries the energy of combustion and explosion, while the cylinder is the working space of the engine piston. The locomotive cylinder body forgings connect the combustion chamber and the cylinder, acting as a seal and support. It can withstand huge forces from extreme working conditions such as high temperature, high pressure and high load, while maintaining the sealing performance and structural stability of the cylinder.

The manufacturing process of locomotive cylinder body forging is very important. First of all, choose high-quality steel as raw materials to ensure that the product has high strength and toughness. Then, through a specific forging process, the grain structure of the steel can be improved, and the strength and toughness of the product are further improved. Next, the precise size control and processing process are carried out to ensure that the accuracy and size of the product meet the design requirements. Finally, heat treatment and surface treatment are carried out to improve the corrosion resistance and durability of the product.

Locomotive cylinder body forging has many excellent features. First of all, it has high strength and precision, and can withstand extreme working conditions and forces to ensure the normal operation and efficient work of the locomotive engine. Secondly, it has good corrosion resistance, can resist the erosion of the medium, extend the service life, and reduce maintenance costs. At the same time, the locomotive cylinder body forging has excellent sealing performance, which can prevent gas and liquid leakage, improve the working efficiency and environmental protection performance of the engine.

Locomotive cylinder body forgings are widely used in various locomotive engines, including diesel engines, electric locomotives, internal combustion engines, etc. It carries important functions and performance requirements, so that it plays a key role in the railway traffic industry. Whether in high-speed trains, regional trains or urban rail transit systems, locomotive cylinder block forging is an important part of ensuring the normal operation and efficient work of locomotive engines.

In short, as a key component of locomotive engine, locomotive cylinder body forgings are manufactured by high-quality materials and specific processes, with excellent characteristics such as high strength, high precision and corrosion resistance. Its application can ensure the stability and reliability of the locomotive engine, and improve the working efficiency and environmental protection performance. In the railway traffic industry, locomotive cylinder body forgings play an important role in providing strong support for safe and reliable railway traffic.

ayu

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.