- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

What is locomotive connecting rod forging?

- Category: Locomotive forging, Steel forgings

- |

- Date: 16/08/2023

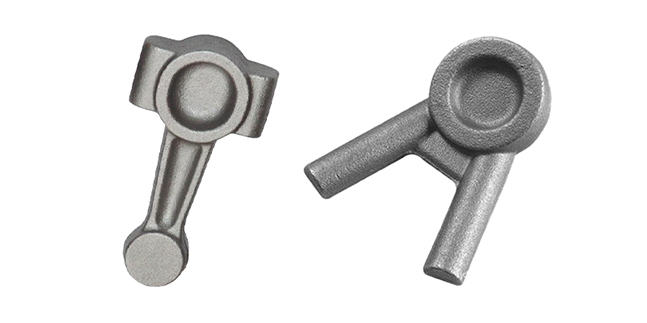

Locomotive connecting rod forging is an indispensable part of the locomotive engine, which is processed by forging process. They have high strength, high precision and excellent fatigue resistance, which can ensure the stable operation and efficient operation of the engine, and provide a reliable and lasting power output for the locomotive.

- Can be customized according to the specific model

Product Details

Locomotive connecting rod forging is an important part of locomotive engine, which is processed by forging process of specific materials. They perform the key function of converting piston movement into crankshaft rotation force and are an integral part of achieving normal operation of locomotive engines and providing power output.

First of all, locomotive connecting rod forging has high strength and high toughness. In the process of locomotive engine operation, the connecting rod bears huge load and impact force. It needs to be able to withstand alternating loads from pistons and crankshafts, and be stable and reliable when rotating at high speeds. Through the forging process, the microscopic grain structure of the material is reshaped and homogenized, thereby improving the strength and toughness of the connecting rod and increasing its resistance to shock and vibration.

Secondly, the locomotive connecting rod forging has excellent accuracy and size control. The working requirements of the engine are very strict on the accuracy and size control of the connecting rod. Any small error can lead to a poor fit between the connecting rod and other key components, resulting in mechanical wear and power loss. Through the forging process, the shape and size of the connecting rod can be effectively controlled to ensure that it is precisely matched with the crankshaft, piston and bearing components, so as to ensure the normal operation and efficient work of the engine.

In addition, locomotive connecting rod forging also has excellent fatigue resistance. The connecting rod is constantly subjected to reciprocating and rotating loads during engine operation, so it must have excellent durability and fatigue resistance. Through the forging process, the internal grain structure of the connecting rod can be improved, the defects can be eliminated, and the fatigue life and reliability can be improved, so as to ensure that the connecting rod can withstand the working state of high strength for a long time.

Locomotive connecting rod forging is widely used in various types of locomotive engines, such as diesel engines, internal combustion engines and electric locomotives. Their high strength, high precision and excellent fatigue resistance ensure the stable operation and effective power output of the engine. At the same time, the manufacturing of connecting rod forgings must also meet strict process standards and quality requirements to ensure their reliability and safety during use.

In short, the locomotive connecting rod forging is an indispensable part of the locomotive engine, which is processed by forging process. They have high strength, high precision and excellent fatigue resistance, which can ensure the stable operation and efficient operation of the engine, and provide a reliable and lasting power output for the locomotive.

ayu

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.