- Contact Innally, Let you purchase forgings in China more favorable prices, products more assured!

- Hotline:+(86)15038323776 Email:innally@innally.com

Properties and application fields of stainless steel forgings

- Category: Aluminium alloy forging, Metal forging

- |

- Date: 08/01/2024

stainless steel forgings, as a high-performance material, have a wide range of applications. Its excellent corrosion resistance, good mechanical properties and machinability make stainless steel forgings an important part of various industries. With the continuous development of science and technology and the increase of application demand, the application prospect of stainless steel forgings will be broader.

Product Details

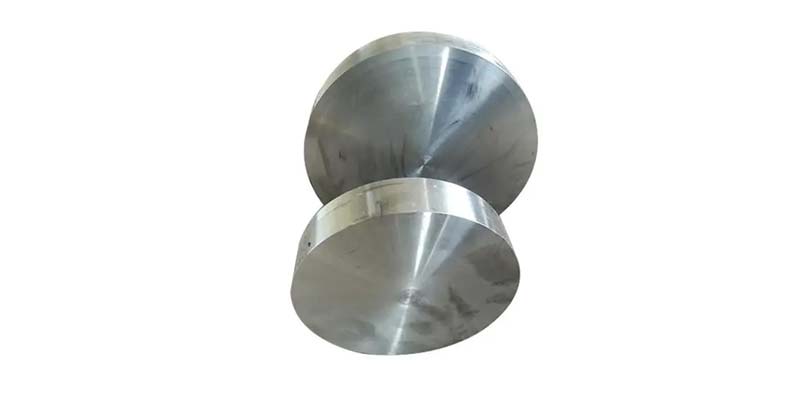

Stainless steel is an alloy steel with excellent corrosion resistance and good mechanical properties. Through the forging process, stainless steel raw materials can be processed into a variety of different shapes and sizes of forgings, widely used in various fields. This paper will focus on the properties of stainless steel forgings and their application fields.

The performance characteristics of stainless steel forgings

Corrosion resistance: Stainless steel forgings have excellent corrosion resistance and can maintain their appearance and performance in a variety of harsh environmental conditions for a long time. This makes stainless steel forgings widely used in chemical, Marine engineering, pharmaceutical and other fields.

Good mechanical properties: stainless steel forgings have high strength, hardness and toughness, and can withstand greater pressure and impact. In addition, stainless steel forgings also have good plasticity and machinability, easy to cut, welding and machining operations.

Good heat treatment performance: stainless steel forgings can be strengthened by heat treatment to further improve their mechanical properties and service life. In addition, stainless steel forgings also have good thermal stability and oxidation resistance, and can be used for a long time in high temperature environments.

Second, the application of stainless steel forgings

Chemical industry: Stainless steel forgings are widely used in the chemical industry to manufacture reactors, pressure vessels, pipelines and other equipment. Due to its excellent corrosion resistance and good mechanical properties, stainless steel forgings can meet the high requirements of chemical equipment.

In the field of Marine engineering, stainless steel forgings are used in the manufacture of ships, offshore platforms, submarine pipelines and other facilities. Its corrosion resistance and good mechanical properties make stainless steel forgings an ideal material in the field of Marine engineering.

Pharmaceutical field: Stainless steel forgings are used in the pharmaceutical field to manufacture pharmaceutical equipment, pipes, valves, etc. Due to its high requirements for the purity and hygiene standards of pharmaceuticals, stainless steel forgings are widely used because of their excellent corrosion resistance and mechanical properties.

Food processing field: In the field of food processing, stainless steel forgings are mainly used in the manufacture of storage tanks, transportation pipelines, food processing equipment, etc. Due to its high requirements for food hygiene and safety, stainless steel forgings have become the preferred material in the field of food processing.

Aerospace field: In the aerospace field, stainless steel forgings are used to manufacture aircraft parts, rocket engine components, etc. Due to its high material requirements and high standards for safety, the application of stainless steel forgings further proves its excellent performance and reliability.

Automotive industry: In the automotive industry, stainless steel forgings are mainly used to manufacture automotive parts, such as engine parts, chassis parts, etc. Due to its corrosion resistance and high strength, it can improve the safety and service life of the car.

Energy field: In the energy field, stainless steel forgings are used in the manufacture of nuclear energy equipment, oil drilling and production equipment. Due to its high requirements for the reliability and safety of materials, the application of stainless steel forgings can ensure the long-term stable operation of energy equipment.

In short, stainless steel forgings, as a high-performance material, have a wide range of applications. Its excellent corrosion resistance, good mechanical properties and machinability make stainless steel forgings an important part of various industries. With the continuous development of science and technology and the increase of application demand, the application prospect of stainless steel forgings will be broader.

nannan

INNALLY mainly provides you with various types of cast and forged parts products. Welcome your inquiries! innally@innally.com

Related Products

Search

Forging center

- Steel forgings

- Aluminium alloy forging

- Titanium alloy forging

- Stainless steel forging

- Copper forging

- Automotive forgings

- Locomotive forging

- Bicycle forgings

- Motorcycle forging

- Rigging and fasteners

- Bearing forging

- Electric power fittings

- Marine forging

- Mechanical forgings for metalworking

- Mining machinery forgings

- Marine engineering forgings

- Construction machinery forgings

Popular product

© 2025. All Rights Reserved.